Compression Seal Expansion Joint for Bridge Construction

a) Rubber Expansion Joint makes bridge smooth and seamless, and it's good for preserving, cleaning and moving snow.

b) The structure is simple, no need to have special stretch frame and anchoring steel bar. Construction is convenient and fast.

c) Rubber Expansion Joint could absorb all kinds of deformations and shaking. And its damping property is high and it's good for bridge shock absorption.

d) Best sealing and waterproof property and anti-acid-base and corrosion.

e) Low cost of construction, durable and remarkable economic benefit and social benefit.

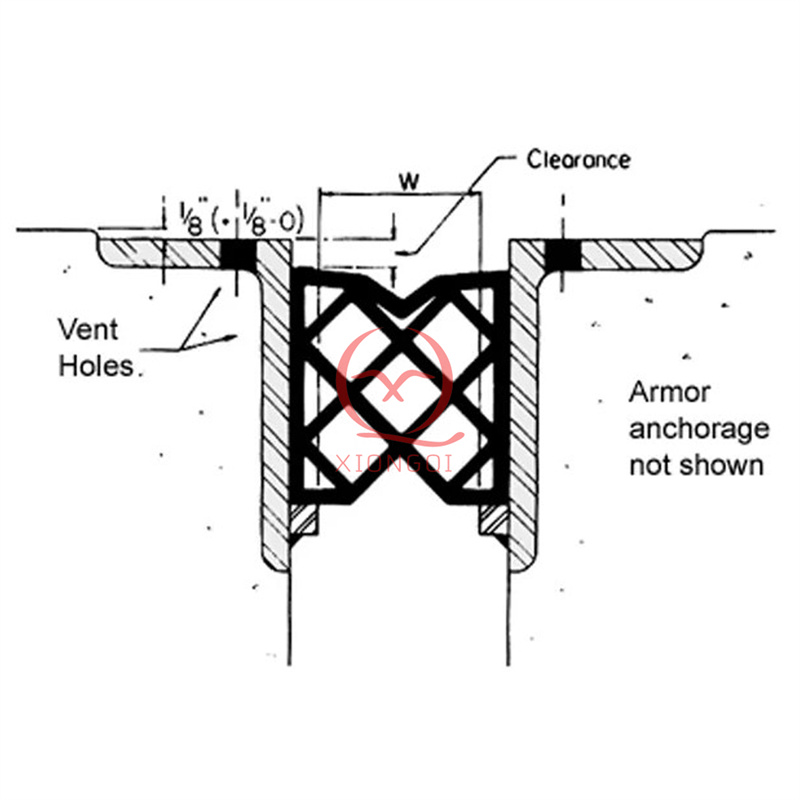

Compression Seal Expansion Joint is provided to ensure water-tightness. The part that has to be inserted into the groove (provided in the edge beam) should have a bulbous shape.

The strip seal shall be of chloroprene with high tear strength, insensitive to oil, gasoline, and ozone. It shall have high resistance to aging. The seal should be vulcanized in a single operation for minimum full length of joint.

1.What is the minimum order quantity for your rubber products?

We didn’t set the minimum order quantity,1~10pcs some client has ordered

2.lf we can get sample of rubber product from you?

Of course, you can. Feel free to contact me about it if you need it.

3. Do we need to charge for customizing our own products?And if it is necessary to make tooling?

if we have the same or similar rubber part, at the same time, you satisfy it.

Nell, you don’t need to open tooling.

New rubber part, you will charge tooling according to the cost of tooling.n additionalif the cost of tooling is more than 1000 USD, we willreturn all of them to you in the future when purchasing orderquantity reach certain quantity our company rule.

4. How long you will get sample of rubber part?

Jsually it is up to complexity degree of rubber part. Usually it take 7 to 10work days.

5. How many your company product rubber parts?

it is up to the size of tooling and the quantity of cavity of tooling.lf rubber part is more complicate and much bigger, well maybe justnake few, but if rubber part is small and simple, the quantity is more than 200,000pcs.

6.Silicone part meet environment standard?

Dur silicone part are allhigh grade 100% pure silicone material. We can offer you certification ROHS and $GS, FDA. Many of ourproducts are exported to European and American countries., Such as: Straw, rubber diaphragm, food mechanical rubber, etc.